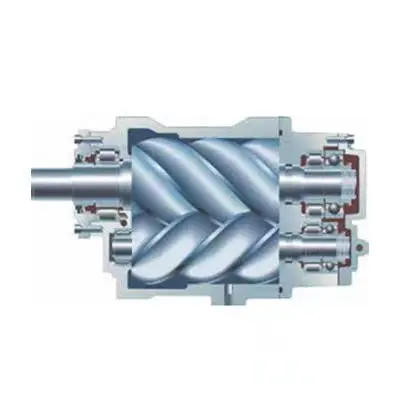

High-Efficiency Energy-Saving Air End

The air compression industry highly recognizes UCS air end with its sophisticated design and precision manufacturing.

By adopting large diameter and the balanced length-diameter ratio of the screw rotors, the optimized design based on the new 4th generation rotor moulded line subjected to higher-efficiency, so that the contact surface, contact line, leak triangle and hydrodynamic characteristics of rotors could reach the optimal performance, further improved the volume efficiency. This screw rotor then has high adiabatic efficiency and low power consumption.

By using imported large-sized heavy-duty bearing and unique bearing layout while ensuring the bearing rigidity, the bearing capacity is much improved, service life lengthened, and its high reliability could keep even under the extreme condition.

The lip type shaft seal of the spiral groove fits with the shaft sleeve made of high-grade bearing steel, ensuring the wear resistance of the shaft seal and shaft sleeve. The shaft seal has a pumping function with high reliability and leakage resistance.