[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

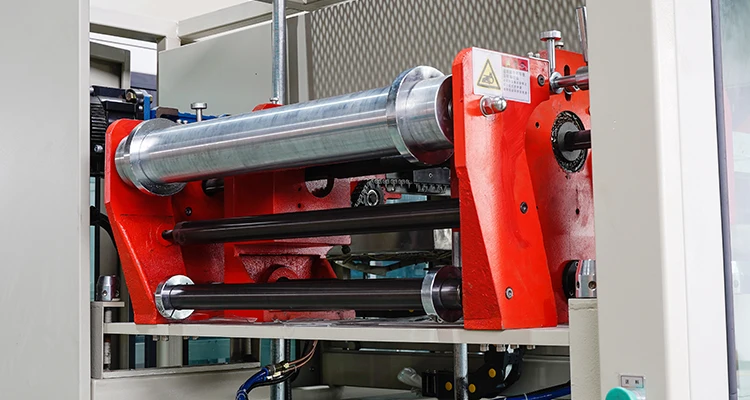

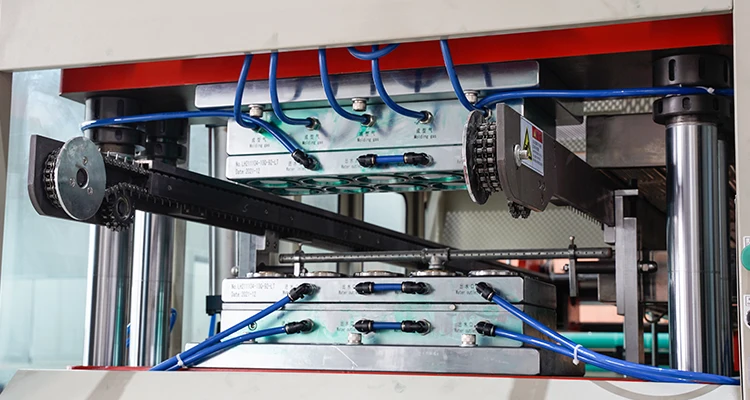

포장 라인이있는 완전 자동 유압 구동 일회용 플라스틱 컵 및 종이컵 플라스틱 뚜껑 기계

포장 라인이있는 완전 자동 유압 구동 일회용 플라스틱 컵 및 종이컵 플라스틱 뚜껑 기계

무상 교체 부품

무상 교체 부품

Technical Parameters | ||||||||

Model | TFC-680 | TQC-750S | TQC-750 | TQC-650B | ||||

Mould Size (Max.) | 680*320mm | 750*480mm | 750*480mm | 650*300mm | ||||

Max. Forming Depth | 170mm | 180mm | 125-180mm(custom height) | |||||

Max. Forming Speed | 42times/min | 30times/min | ||||||

Sheet Thickness | 0.3-2.0mm | 0.3-1.8mm | ||||||

Max.Sheet Width | 730mm | 760mm | 660mm | |||||

Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. | |||||||

Air Pressure | 0.8-1.0mpa | 0.6-0.8mpa | ||||||

Air Consumption | 4-5m³/min | 3.0m³/min | 2.0m³/min | |||||

Water Consumption | 15.6m³/h | 0.7m³/h | 0.5m³/h | |||||

Rated Power | 174Kw | 173Kw | 98Kw | |||||

Heating Power | 132Kw | 146Kw | 78Kw | |||||

Power Supply | AC 380V,50Hz, Three-phase, Four-wire | |||||||

Dimension | L10700*W3088*H3215mm | L9000*W2305*H3190mm | L8500*W2200*H3200mm | L7000*W2000*H3100mm | ||||

Weight | About 13.5T | About 7.7T | About 6.5T | About 5T | ||||

Main Electrical Components | ||||||

MODEL/PARTS | TQC-750S | TQC-750 | TQC-650B | |||

Touch Screen | SIEMENS(Germany) | |||||

PLC | SIEMENS(Germany) | |||||

Driver | SIEMENS(Germany) | YASKAWA(Japan) | ||||

Servo motor | INOVANCE(CHINA) | YASKAWA(Japan) | ||||

Forming Valve | MAC(America) | |||||

Heater | Trimble(China)/ELSTEIN(Germany) | Trimble(China) | ||||

Power switch | MEAN WELL(Taiwan) | |||||

Contactor | SCHNEIDER(France) | |||||

Circuit Breaker | SCHNEIDER(France) | |||||

Proximity Switch | FOTEK(Taiwan) | |||||

Solid State Relay | FOTEK(Taiwan) | FOTEK(Taiwan)、AOYI(CHINA) | ||||

Cylinder | KaoGeer(China) | |||||

Chovm.com에서 진행하는 모든 결제는 엄격한 SSL 암호화 및 PCI DSS 데이터 보호 프로토콜을 통해 보호됩니다

주문한 상품이 배송되지 않거나, 누락되었거나, 제품에 문제가 있는 상태로 도착하는 경우 환불을 청구하세요

무료 부품 교체 및 수리 서비스 제공