[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

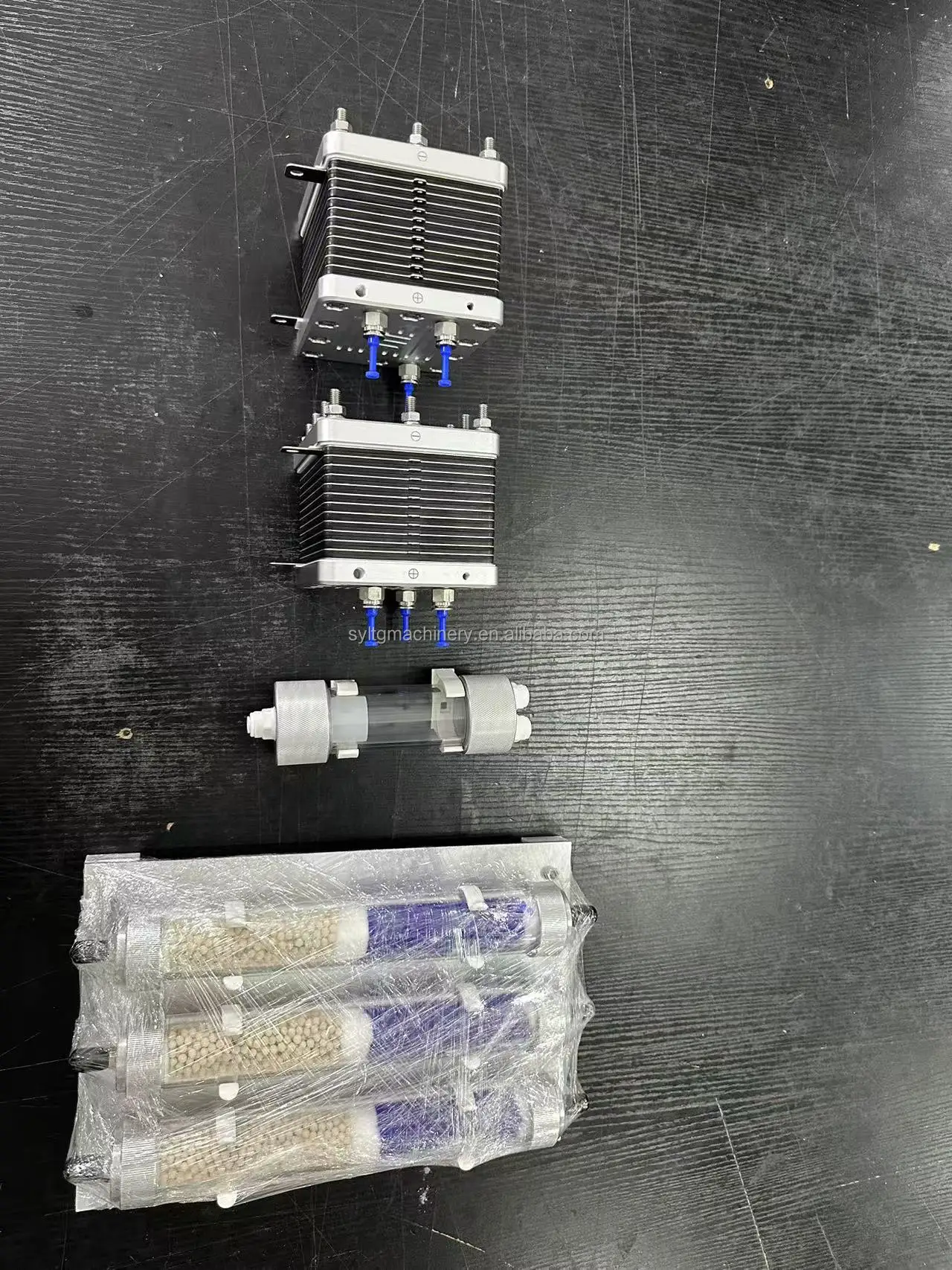

무상 교체 부품

무상 교체 부품

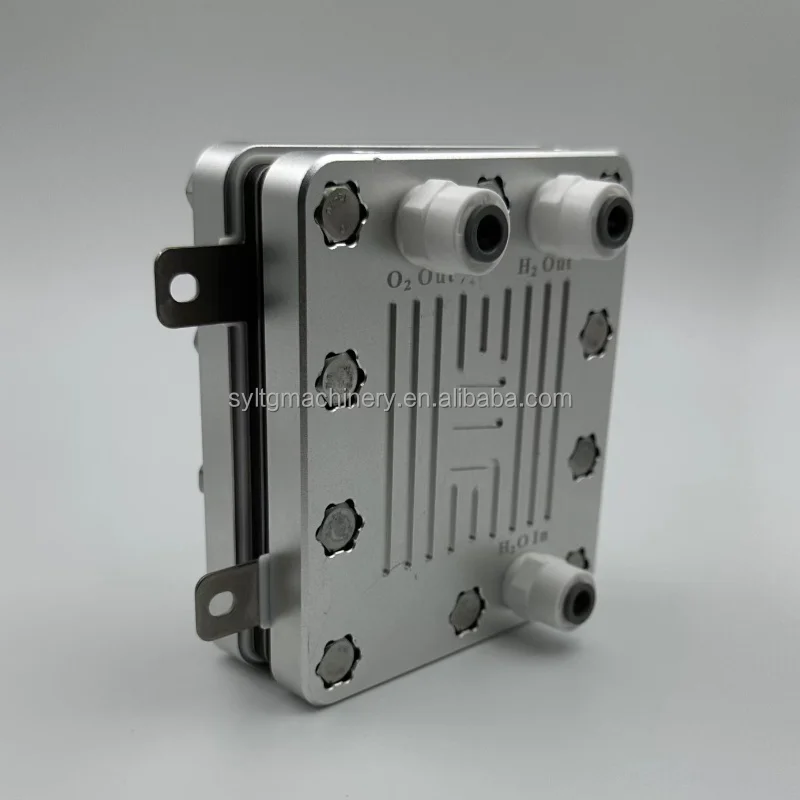

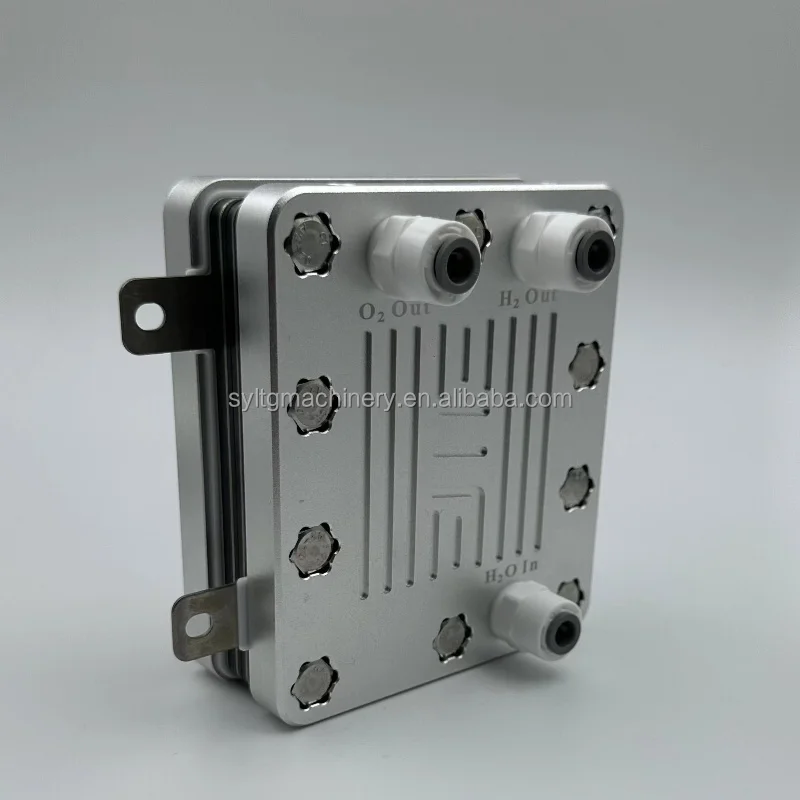

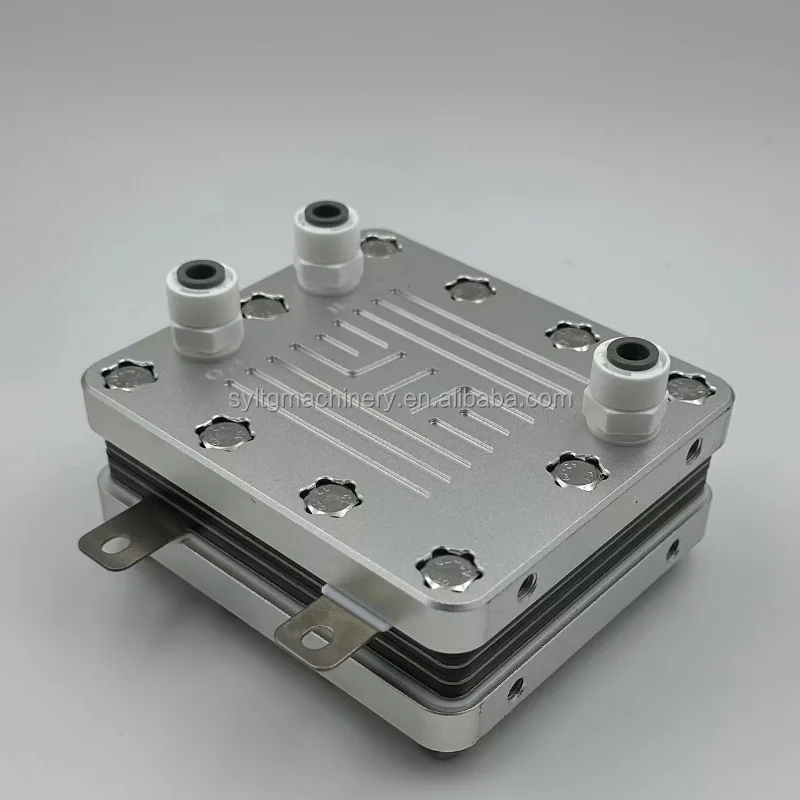

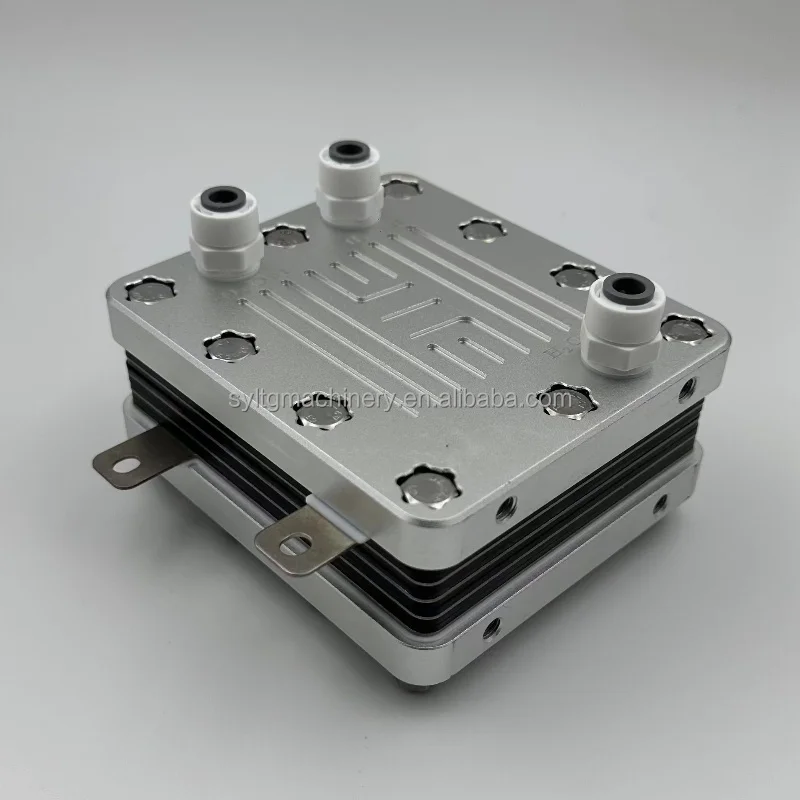

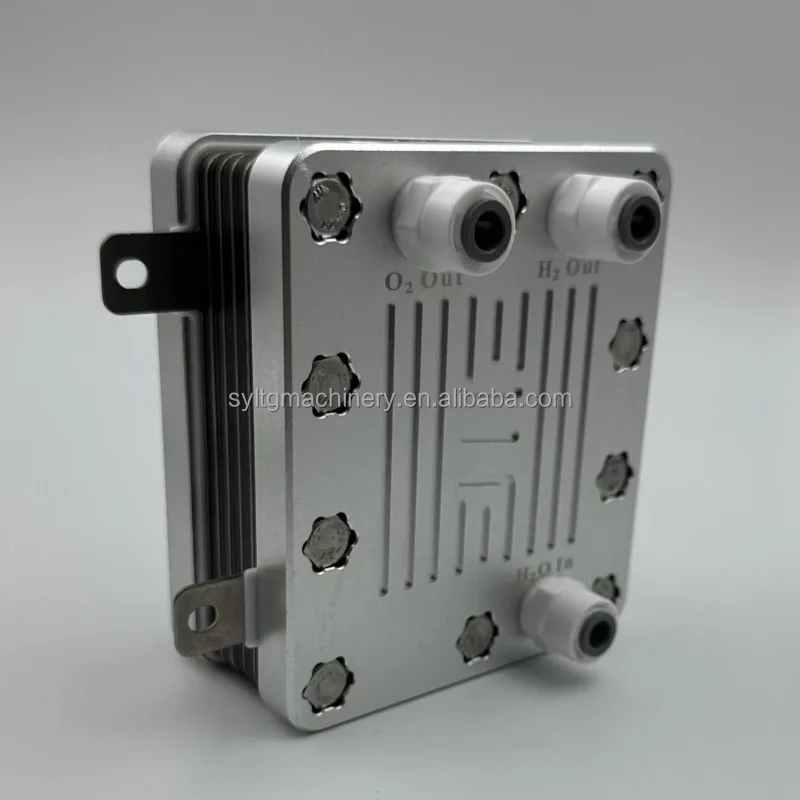

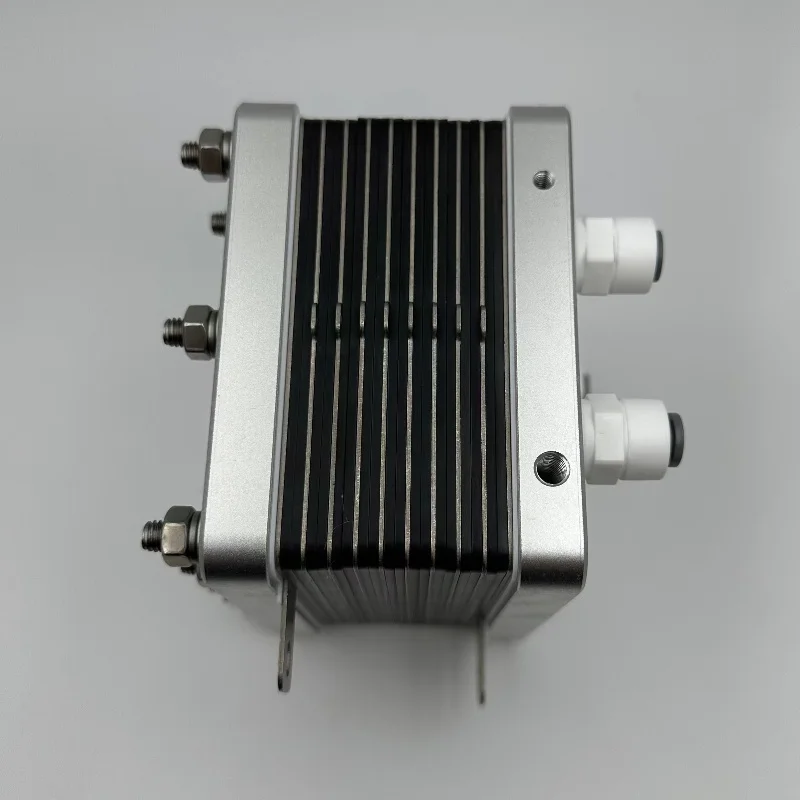

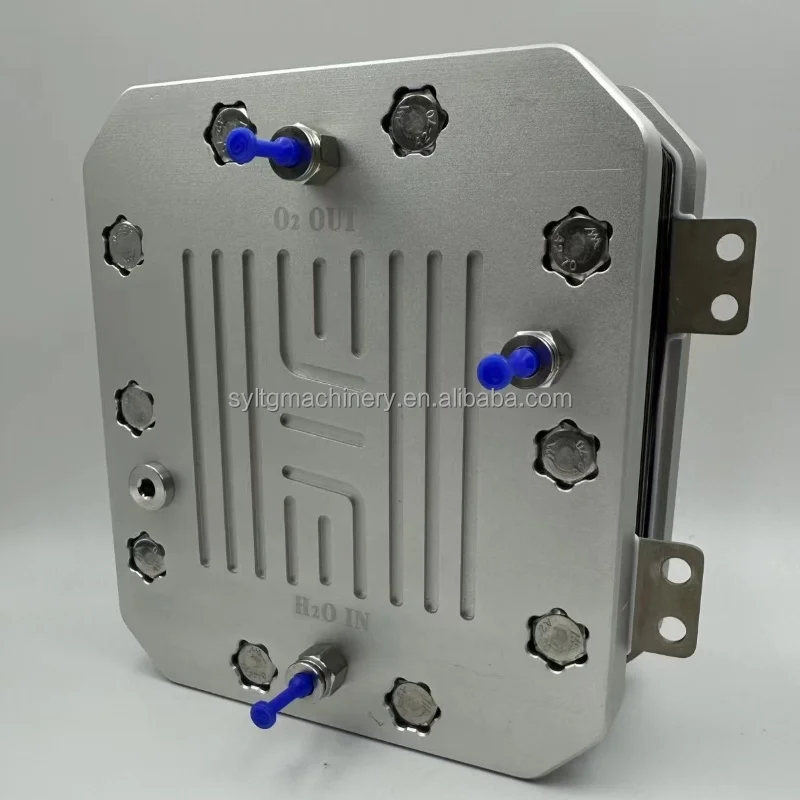

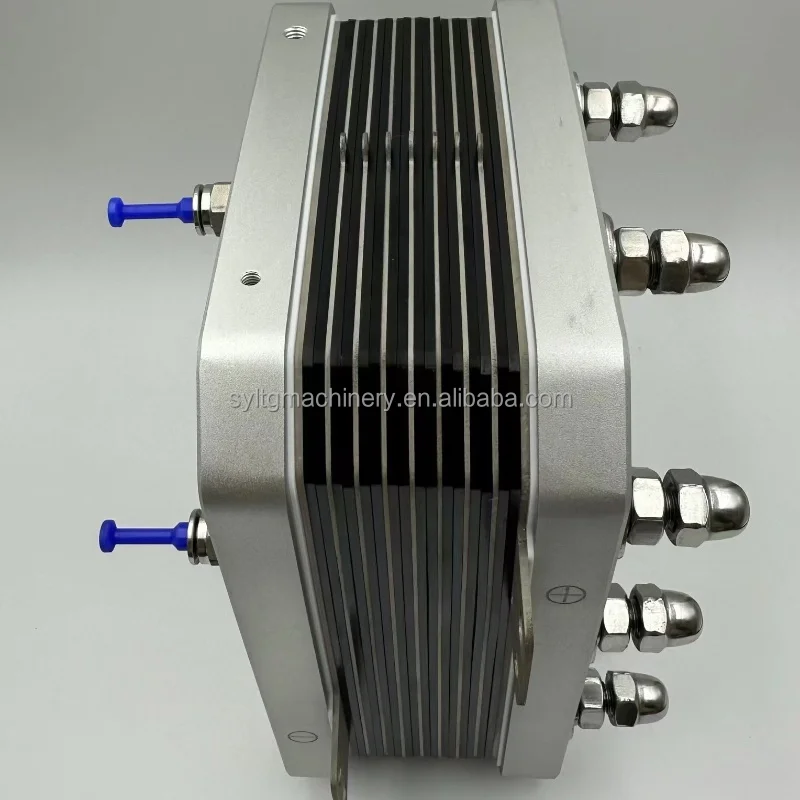

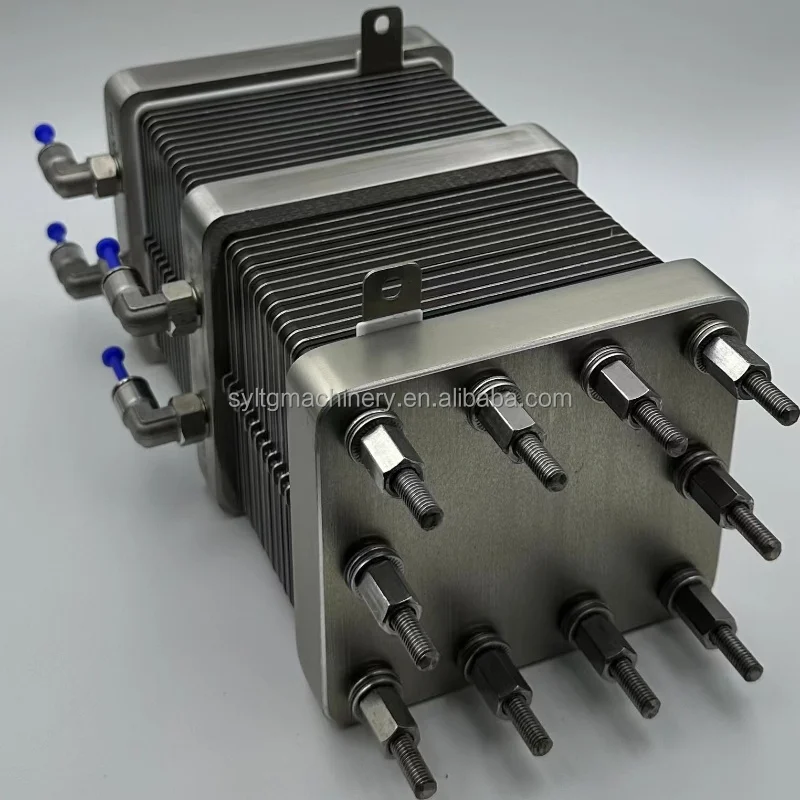

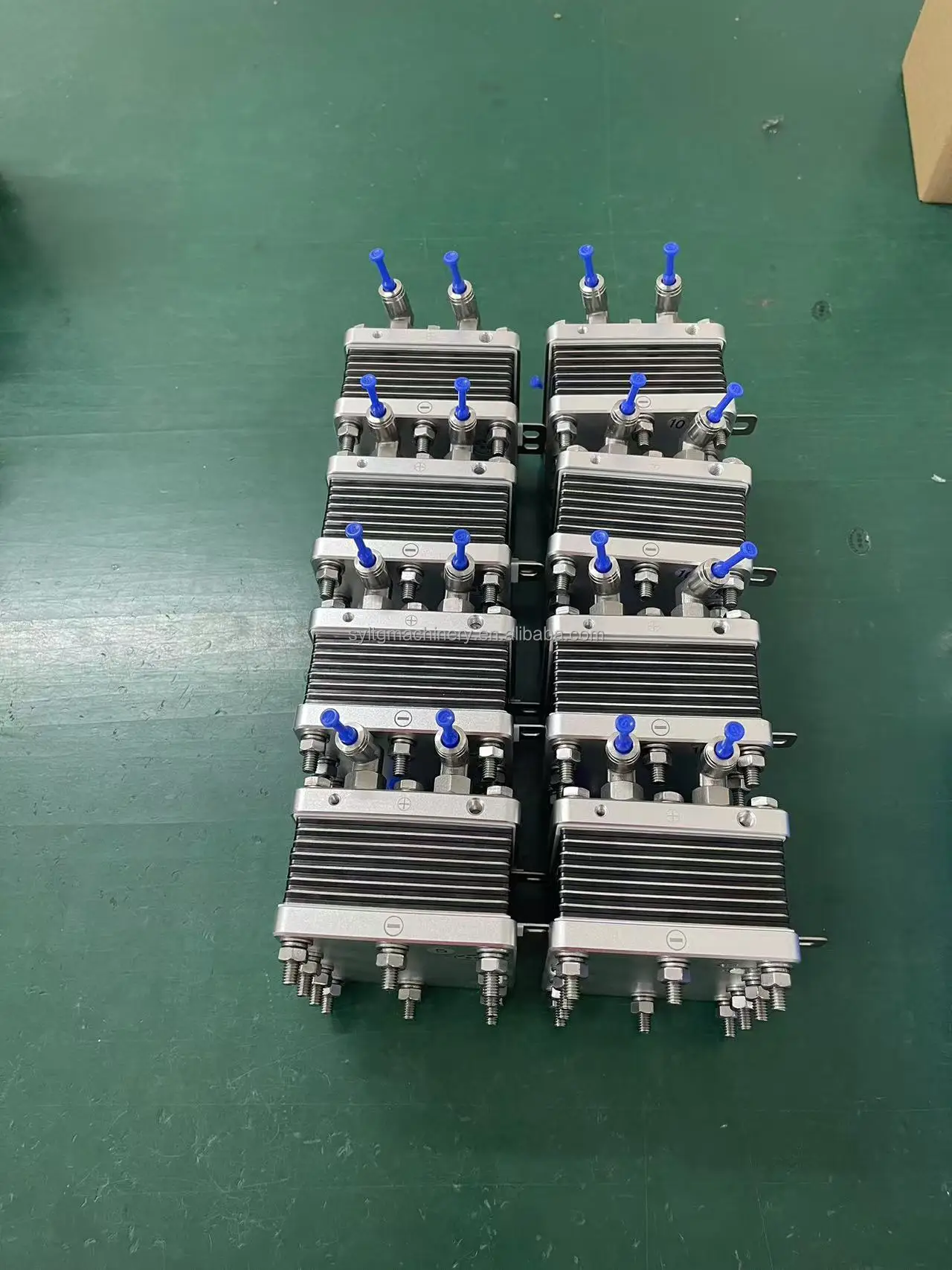

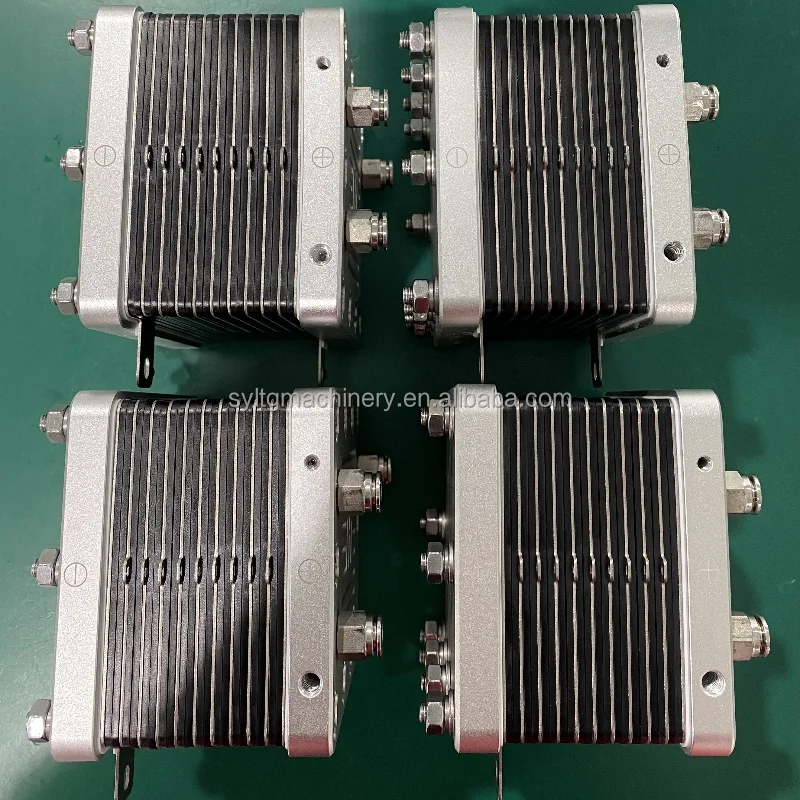

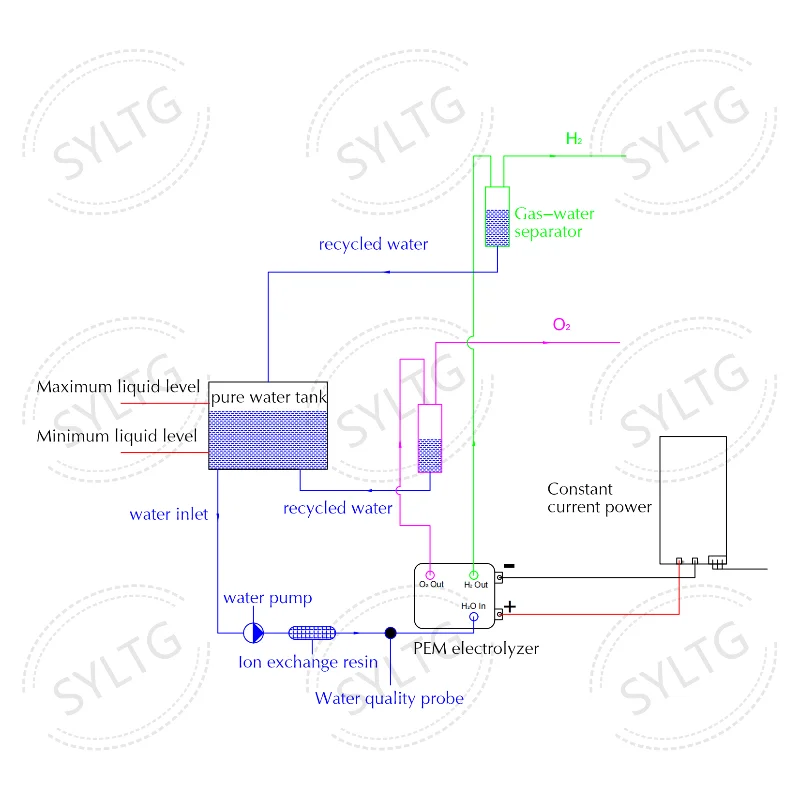

Product model | Hydrogen production | Oxygen production | Water consumption | Recommended pressure | Current rating | Output voltage |

4000-HB6 | 4000 ml/min | Pure hydrogen | 480 ml/h | 0.1 ~ 1.3 MPa | 67A | 24V |

50-HB4 | 50 ml/min | 25 ml/min | 6 ml/h | 0.1 ~ 1.0 MPa | 7A | 3.5V |

100-HB4 | 100 ml/min | 50 ml/min | 12 ml/h | 0.1 ~ 1.3 MPa | 13A | 3.5V |

150-HB4 | 150 ml/min | 75 ml/min | 18 ml/h | 0.1~1.3 MPa | 20A | 3.5V |

200-HB6 | 200 ml/min | 100 ml/min | 36 ml/h | 0.1~1.3 MPa | 25A | 3.5 V |

300-HB4 | 300 ml/min | 150 ml/min | 36 ml/h | 0.1~1.3 MPa | 20A | 7 V |

400-HB4 | 400 ml/min | 200 ml/min | 36 ml/h | 0.1~1.3 MPa | 26A | 7 V |

450-HB4 | 450 ml/min | 225 ml/min | 54 ml/h | 0.1~1.3 MPa | 20A | 9 V |

600-HB6 | 600 ml/min | 300 ml/min | 72 ml/h | 0.1~1.3 MPa | 20A | 12 V |

800-HB6 | 800 ml/min | 400 ml/min | 100 ml/h | 0.1~1.3 MPa | 25A | 12V |

1000-HB6 | 1000 ml/min | 500 ml/min | 120 ml/h | 0.1~1.3 MPa | 25A | 15 V |

1200-HB6 | 1200 ml/min | 600 ml/min | 144 ml/h | 0.1~1.3 MPa | 25A | 18 V |

1400-HB6 | 1400 ml/min | 700 ml/min | 168 ml/h | 0.1~1.3 MPa | 25A | 21 V |

1600-HB6 | 1600 ml/min | 800 ml/min | 192 ml/h | 0.1~1.3 MPa | 25A | 24 V |

1800-HB6 | 1800 ml/min | 900 ml/min | 216 ml/h | 0.1~1.3 MPa | 25A | 27 V |

2000-HB6 | 2000 ml/min | 1000 ml/min | 240 ml/h | 0.1~1.3 MPa | 25A | 30 V |

2250-HB6 | 2250 ml/min | 1125 ml/min | 248 ml/h | 0.1~1.3 MPa | 28A | 30V |

2500-HB6 | 2500 ml/min | 1250 ml/min | 256ml/h | 0.1~1.3 MPa | 26.5V | 36V |

3000-HB6 | 3000 ml/min | 1500 ml/min | 264 ml/h | 0.1~1.3 MPa | 32A | 36V |

3500-HB6 | 3500 ml/min | 1750 ml/min | 284 ml/h | 0.1~1.3 MPa | 34A | 39V |

3750-HB6 | 3750 ml/min | 1875 ml/min | 294 ml/h | 0.1~1.3 MPa | 36A | 39V |

3000-HB6 thickened end plate 15 layers | 3000 ml/min | 1500 ml/min | / | 0.1~1.3 MPa | 25A | 45V |

4000-HB6 three-layer custom end plate | 4000 ml/min | 2000 ml/min | / | 0.1~1.3 MPa | 25A | 60V |

4000-HB6, with the new 82 model, 8P | 4000 ml/min | 2000 ml/min | / | 0.1~1.3 MPa | 67A | 24V |

4500-HB6, with the new 82 model, 9P | 4500 ml/min | 2250 ml/min | / | 0.1~1.3 MPa | 67A | 27V |

5000-HB6, with the new 82 model, 10P | 5000 ml/min | 2500 ml/min | / | 0.1~1.3 MPa | 67A | 30V |

5500-HB6, with the new 82 model, 11P | 5500 ml/min | 2750 ml/min | / | 0.1~1.3 MPa | 67A | 33V |

6000-HB6, with the new 82 model, 12P | 6000 ml/min | 3000 ml/min | / | 0.1~1.3 MPa | 67A | 36V |

주문하신 상품이 예정일까지 배송되며 지연된 경우 10%의 지연 보상을 받으실 수 있습니다

Chovm.com에서 진행하는 모든 결제는 엄격한 SSL 암호화 및 PCI DSS 데이터 보호 프로토콜을 통해 보호됩니다

주문한 상품이 배송되지 않거나, 누락되었거나, 제품에 문제가 있는 상태로 도착하는 경우 환불을 청구하세요

무료 부품 교체 및 수리 서비스 제공